11.09.2017

September 2017 – Enerdoor’s Pre-compliance Testing Saves Time and Money

Published on: 11/09/2017

Introducing Enerdoor’s new on-site pre-compliance testing service

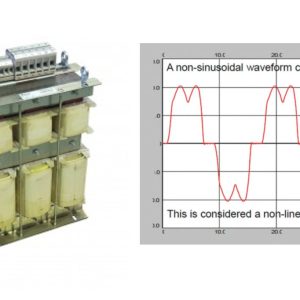

Today lasers are used in several markets, including: medical, machine tools, microelectronics, marking and advanced processing. All electronic devices have connections that are potential sources for electromagnetic or radio frequency interference (EMI/RFI). Both are known as electrical noise which may cause disturbance in normal operations.

They can cause unexpected issues to occur, audible noise problems such as leaking water are visible and can be detected by a person hearing or seeing the issue, however electrical noise is a type of problem that can only be solved after careful analysis using specialised equipment.

Enerdoor’s Pre-compliance Testing

Enerdoor understand that these issues occur which is why they have launched flat rate on-site pre-compliance testing before moving to the final compliance test which saves their customers time and money. They know that a machine compliance failure can compromise a projects deadline and release date and identified pre-compliance testing as a great solution for improving a products chance of passing EMC testing and lowering the risk of failure.

Enerdoor is allowing manufacturers to bring a product to the global market faster, while being in complete compliance and at a reduced total cost. Enerdoor is committed to providing the highest level of customer support possible to service and satisfy its customers.

GD Rectifiers are an authorised distributor for Enerdoor products, including: Motor Protection, Harmonic Filters, Power Factor Correction, Surge Arresters, Voltage Stabilizers and EMI/EFI/EMC Filters.

For further information on Enerdoor’s pre-compliance testing services please contact GD Rectifiers on: 01444 243 452 or email: enquiries@gdrectifiers.co.uk.