LED Lighting

LEDs provide a better and safer light source by using a semiconductor to convert electricity into light.

Over the past 50 years LEDs have been used in every application imaginable, from car headlights to lighting our homes.

Benefit from increased energy efficiency, a cost-effective and longer bulb life solution for companies.

LED (light-emitting diode) lighting is a reliable, energy efficient and cost effective alternative to the conventional incandescent lights considered the preferable lighting choice until recently. LED Lights can last up to 100,000 hours (over 11 years) compared to a very small life of an incandescent bulb. They are much more energy efficient as their consumption of electricity is lesser than the incandescent bulbs.

Today LEDs are most commonly used in applications such as: televisions, smart phones, tablets, traffic lights, car headlights and outdoor lighting.

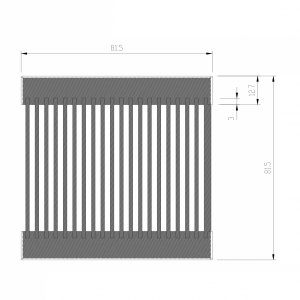

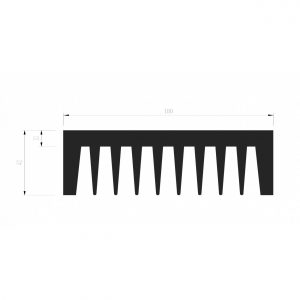

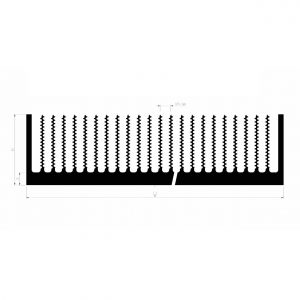

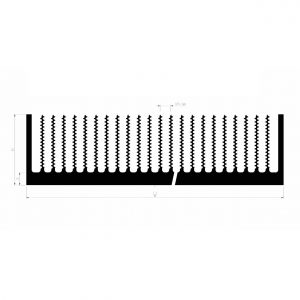

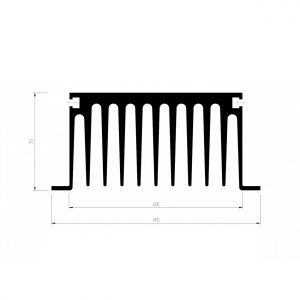

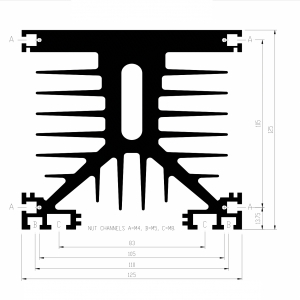

Aluminium Heatsinks are an important cooling solution for most of today’s electronics. Heatsinks are becoming an increasingly popular thermal management solution for LED lighting because too much heat can damage LED phosphor which would result in lower light output, a change in colour and a significant decrease to its life expectancy.

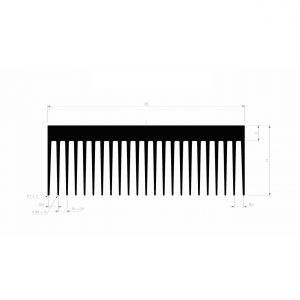

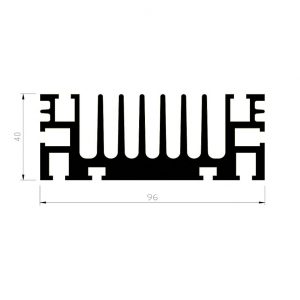

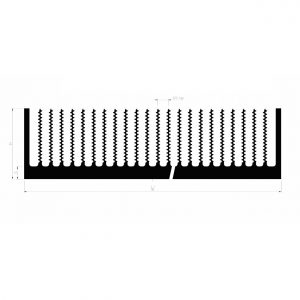

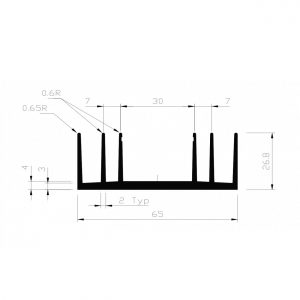

The most common problem that we see in LED lighting applications stem from too small of a heatsink or sometimes none at all. At GD Rectifiers, we work with LED Lighting manufacturers to offer a wide variety of LED Heatsinks which include black anodised extruded aluminium heatsinks, clear anodised extruded aluminium heatsinks and forced air cooled aluminium heatsinks.

How Does It Work?

Aluminium Heatsinks used with LEDs are designed to absorb and disperse heat away from the LED light and in to the heatsink. Either passive or active air then circulates around the heat sink to help cool it.

Heatsinks absorb heat from the LED light and dissipates it outside, there are a several factors that affect the performance of the heatsink.

Factors Affecting LED Heatsink Performance

- Heatsink Size – the surface area of the heatsink needs to be large, a higher surface area can be achieved by increasing the number of fins in the heatsink or by increasing the overall size of the heatsink too

- Surface of the Heatsink – if a Heatsink is anodised, the dissipation of the heat is improved. The Heatsink effect is even more prominent when the transfer of heat is done by radiation of heat to the outside

- Orientation – the orientation of the light source on the LED Heatsink has an effect on the overall Heatsink

- Material – Copper, stainless steel and aluminium are all popular heatsink materials. Aluminium has a decent heat conduction capacity (which is better than stainless steel but less than Copper) and is the most cost effective material used for Heatsinks. Aluminium is the most commonly used material for LED Heatsinks because it is a good conductor, it is the preferred material and is used in most luminaries in the industry.

Reasons Why You Should Use LED Lighting

- LED lights will save you electricity because they require less energy to power

- They will save you approximately 80% of electrical power compared to incandescent bulbs

- LED lights do not contain hazardous solids, liquids or gases

- LED lights are a popular choice as automobile lighting because they have been proven to help reduce the risk of car accidents in daylight hours by 15%

- They are becoming increasingly popular amongst consumers, opting to invest in LED lights and choose from a number of different colours to define their style and desired ambience

- LED Lights use direct light which means there is no light pollution

- LED lights contain no UV light, eliminating the possibility of skin damage

- They provide local lighting solutions and improve visibility on the roads

- These lights do not require excessive maintenance once they’re installed

- LED lights last 2400% longer than regular halogen bulbs and can last up to 50,000 hours

- One major benefit of LED lights is that they immediately switch on without requiring a warm-up time

- LED lights are extremely reliable and are fully operational in all weather conditions

- LED lights are lightweight and recyclable

- They are much brighter than traditional lighting solutions, offering improved visibility and performance

- Another major benefit is because LED lights are environmentally friendly, they lower your carbon footprint

- LED lights do not emit radio frequency interference

- LED lights save consumers a lot of money on their electricity bills

- They can be used inside and outside your home

- LEDs are much cooler than incandescent lights which reduces the risk of combustion

- LED lights are made with epoxy lenses instead of glass which makes them much more resistant to breakage

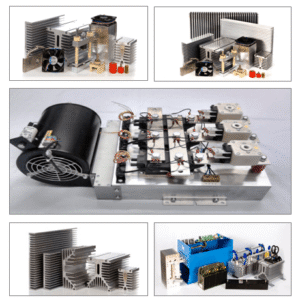

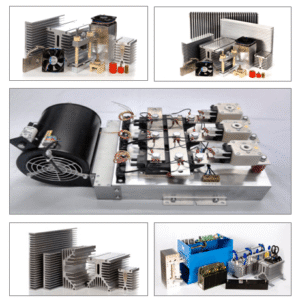

We have a vast range of experience in designing and manufacturing heatsinks for LED applications, utilising extruded and cast solutions.

We’ve worked with some of the UK’s leading lighting companies and design houses to develop pioneering LED lighting cooling requirements, we work closely with our customers on the design and build of customised solutions providing technical advice, expertise and support every step of the way.

Related Products

Our specialist products, components and designs can be found in a wide range of LED applications around the world. We also partner with customers to design custom components and devices to suit their requirements.

Related News

14.06.2022

February 2019 – GD Rectifiers helps Crossrail lead the way for LED Lighting

GD Rectifiers supplies LED heatsinks to Crossrail Crossrail station, Tottenham Court Road. Credit: Crossrail Transport for London made the decision to use LEDs to light the stations, escalator shafts and concourses back in 2013 in order to reap the benefits of reduced energy consumption and maintenance requirements, delivering a significant reduction in the overall […]

14.06.2022

March 2018 – Heat Dissipation Solutions

Published on: 27/03/2018 Explore your heat dissipation options for your next project today Heat dissipation, often known as thermal management is required in all electronic devices and circuitry to prevent the devices from overheating. Heat dissipation devices increase a products reliability and helps prevent premature failure. GD Rectifiers offers a wide range of […]