17.10.2016

October 2016 – Top 10 Interesting Facts About Heat Sinks

Published on: 17/10/2016

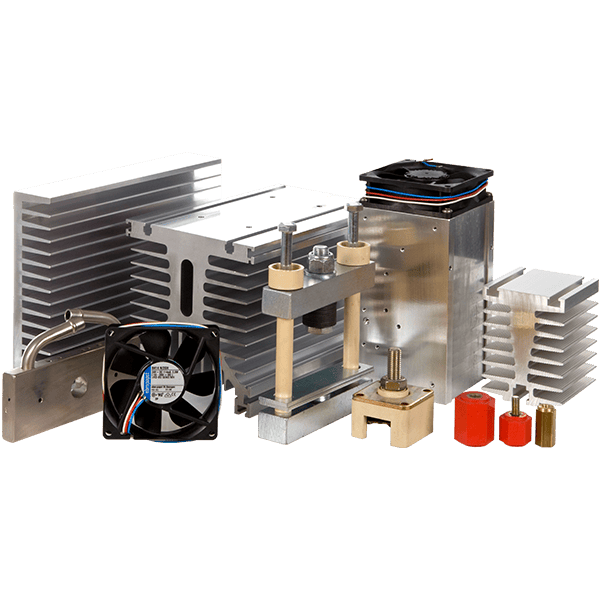

Discover the top 10 interesting facts about heat sinks; from technical product insight to popular applications and market value

A heat sink is a thermal device that dissipates heat from another object. It transfers heat generated by a mechanical or electronic device to a fluid medium which is normally air or liquid coolant where it is dispersed away from the device.

Top 10 Interesting Facts About Heat Sinks:

1. A heat sinks performance is improved by accelerating air velocity using fan cooling

2. Without a heat sink, a computer is likely to overheat within 30 seconds

3. Today, heat sinks are used in a wide range of products, from large applications such as an aeroplane to smaller consumables such as mobile phones

4. The global aluminum heat sink market will be worth $2.23 billion by 2018

5. Extrusion heat sinks own 83% of the heat sink market, whilst inserte-type heat sinks own just 17%

6. The Sandia National Laboratory has designed a new air-cooling technology – the Sandia Cooler. It improves the way heat is transferred in computers and microelectronics, significantly reducing the energy needed to cool CPUs in data centres. If the technology can be applied to other applications such as heating, ventilation and air conditioning, researchers say the Sandia Cooler has the potential to decrease overall power consumption in the USA by 7 percent.

7. A heat sinks performance is improved by increasing convective air velocity

8. A robust and rapid development in technology with increased usage of microprocessors is propelling growth in the heat sinks market. USA, Japan and Europe are the key regions while emerging markets include: Asia Pacific and Rest of World that include Latin America are the fastest growing regional markets

9. Spread power evenly over the heat sink provides a better performance

10. Black anodizing can improve thermal impedance by 10-12%

GD Rectifiers are the UK’s leading manufacturer of standard and custom made heatsinks, heat sink accessories and heat sink assemblies. They stock and machine the largest range of heatsinks suitable for stud, modules and capsule semiconductors plus high power LED applications. Offering a full service from design to production, technical support and fast delivery, GD Rectifiers is the No.1 heat sink provider in the UK.

GD Rectifiers are experts in Thermal Management, Standard & Custom Made Heat sinks, Cold Plates, Liquid Cooling Solutions and Thermal Assemblies. Offering an extensive range of Air Cooled and Aluminum Heat sinks, they have a wide selection of high quality heat sinks readily available in stock at unbeatable prices and offer a next day delivery service.

Browse the complete heat sink range by device type, part number or comparison guide here.

GD Rectifiers offer technical support on all heat sinks including specific heat dissipation requirements. We also provide a power assembly design and manufacturing service, and can build tailor made assemblies with your preferred semiconductor components, or by using our own stocked devices from Semikron, IXYS, and IXYS UK Westcode.

For further information on all heat sink products click here or alternatively call our friendly sales team for a quote today on: 01444 243 452.

Find out more about the latest GD Rectifiers product range here.