28.06.2019

June 2019 – Datasheets Made Easy

Published on: 28/06/2019

Datasheets made easy; discover our useful tips on how to interpret complex datasheets for power supplies

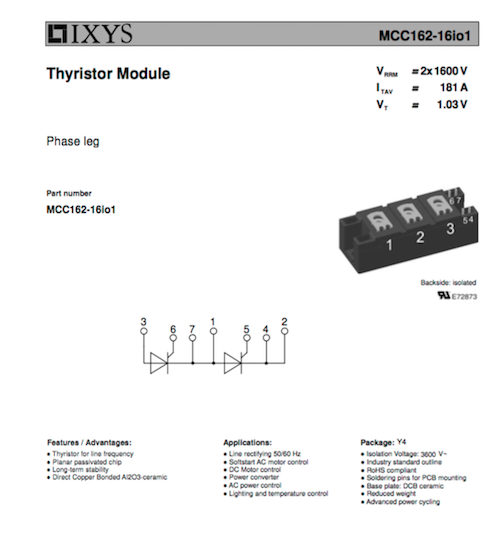

IXYS Thyristor module MCC162-16io1 datasheet example

Datasheets Made Easy

Datasheets are a key source for technical information, however nowadays they often include everything from voltage and temperature combinations, to certifications, testing procedures and technical drawings, making it difficult and time consuming for buyers to digest them.

With operating temperatures and safety specifications for electronic components continuing to become more complex, adding to the length, level of detail and complexity of datasheets, GD Rectifiers have compiled an easy guide to helping you understand todays’ datasheets.

Interchangeable Devices

Customers today are looking to streamline their buying process and invest in interchangeable devices so they can do more with fewer devices. This puts pressure on manufacturers who now have to offer electronic components that can fit a variety of potential applications and make sure all relevant information is listed on the datasheet.

Today, manufacturers have to offer power components with variable output voltages in addition to offering fixed voltage devices because having a variable voltage lets customers adjust the power output to their preferred level, allowing the device to be used across numerous applications.

In addition to the interchangeable demand of components, they also have to meet strict and rigorous requirements that are application and part-specific for electrical testing.

Industry Standards

Every industry follows strict standards that outlines the specifications of electronic components used throughout the various applications, e.g. BS EN 50155 outlines specifications used on rolling stock for railway applications. This European standard applies to all electronic equipment for control, regulations, protection, diagnostic and energy supply.

Industry standards cover the operation, design, documentation and testing of electronic equipment in order to ensure its conformity and reliability for purpose. These specific requirements relate to practices necessary to ensure defined levels of functional safety, relevant to industry safety standards.

Another sector which has to follow the strictest industry standards is the medical industry, they have to ensure all electronic components are tested for EMI, leakage current and voltage isolation. The medical industry has to perform high potential tests which verifies the devices electrical insulation to ensure it protects patients coming in to contact with medical equipment. Whilst components are already tested and meet the relevant standards, each industry is responsible for the safety of their equipment and manufacturers are required to list the various tests and results on their datasheets.

Key Information

Datasheets can sometimes be overwhelming and it can take buyers and procurement specialists a long time to digest the necessary information they need to pass on to their customers. When looking at component datasheets, the key and initial information to highlight to your customers is: device features, advantages of the device over any others being considered, availability, suitable applications, the type of package, maximum voltage rating and operating temperature. Customers will often make their decision on whether they intend to buy the part based on the seven points above, unless the part is for a new design in which case a more rigorous screening process to ascertain the parts compatibility is often required.

Thermal Management

Many applications demand wider input ranges, higher power in smaller packages and installation in in environments with high ambient temperatures and limited cooling.

In some devices, the wider input can reduce the overall efficiency of the power supply which affects the amount of waste heat produced. The less heat waste there is, the closer components can be mounted together without exceeding their specification which reduces the overall power supply size.

Thermal management is a key consideration to pass on to customers and often gets overlooked. Mounting and remote placement options are a key consideration when choosing components, today customers demand smaller power supply packages, and manufacturers have responded to this demand by providing more mounting and remote placement options such as DIN-rail, open-frame and enclosed, terminal block and surface mount types.

Over the last few years’ datasheets have become longer due to the increase in safety specifications and the addition of new products complying with industry standards. Certifications, testing procedures, model numbers and designations prove extremely useful with end-users.

Although datasheets today are much more complex than in previous years, they serve a purpose to engineers in the industry, particularly to those in the rail and medical sectors who need an abundance of data before procuring products.

Datasheets are enormously important and are a key source for customers to select appropriate power supplies for new designs, existing units or refurbishing jobs and obsolescence procurement.

GD Rectifiers provides datasheets for power supplies from over 20 manufacturers on their website, shop by product here.

For further support on datasheets or to discuss your requirements, please contact us on: 01444 243 452 or email: enquiries@gdrectifiers.co.uk.